MOL, Kinetics Team Up to Develop World's First Integrated Floating Data Center Platform

CG rendering of powership and offshore data center. Photo courtesy of MOL.

CG rendering of powership and offshore data center. Photo courtesy of MOL.

Mitsui O.S.K. Lines, Ltd. (“MOL”), one of the world's leading shipping companies, has signed a Memorandum of Understanding (“MOU”) with Kinetics, the energy transition initiative of global floating power leader Karpowership, to jointly develop a next-generation Floating Data Center platform.

Under the MOU, the two companies will collaborate on the design, construction and deployment of a state-of-the-art data center hosted on a retrofitted vessel. The facility will be supplied with uninterrupted, dedicated power from a range of flexible sources, including Powerships developed by Karpowership, as well as options to integrate land-based grids, onshore solar farms, offshore wind, or other power generation solutions depending on project location and client requirements. Karpowership, a pioneer in integrated floating power solutions, brings over two decades of operational experience with more than 10,000 MW of installed capacity across 19 countries.

This partnership combines Kinetics' expertise in mobile energy infrastructure with MOL's extensive maritime and offshore logistics capabilities to address the surging global demand for digital infrastructure. The floating platform will offer a scalable, mobile, and rapidly deployable alternative to traditional land-based data centers, overcoming the challenges of power constraints, land scarcity, and permitting delays.

"This project represents a significant step toward our vision at Kinetics: delivering innovative, efficient, and sustainable infrastructure solutions that meet the energy needs of today and tomorrow", said Mehmet Katmer, chief executive officer of kinetics. "By pairing mobile power generation with floating data infrastructure, we are addressing critical market bottlenecks while enabling faster, cleaner and more flexible digital capacity expansion".

"This MOU represents an important step forward in leveraging the MOL Group's assets and extensive expertise in ship operations to rapidly build digital infrastructure while minimizing environmental impact,” said Tomoaki Ichida, managing executive officer of MOL. “Moving forward, we will continue to expand a diverse range of social infrastructure businesses centered on the shipping industry. Through the advancement of our technologies and services, we are committed to proactively responding to society's evolving needs, including the imperative of environmental conservation".

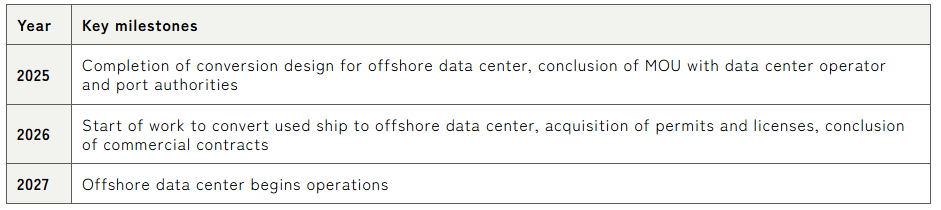

This MOU marks the first dedicated collaboration between the companies towards delivering sustainable solutions for the digital age. Following successful feasibility studies and ongoing technical developments, the first Floating Data Center project is targeted for deployment in 2027.

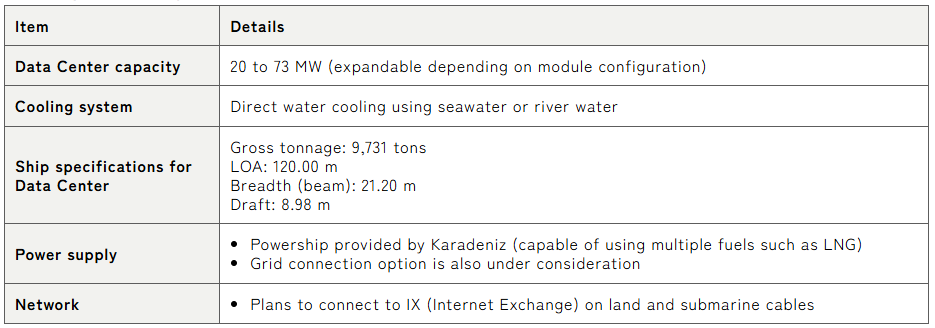

Pilot Project Summary

Project Timeline

Advantages of offshore data center compared to land-based facility

- Offshore data centers can be operated independently of the local power supply, by combining it with a powership. In the U.S., power companies are unable to keep up with demand, resulting in wait times of more than five years before data centers can begin operations. Even in areas experiencing power shortages, offshore data centers can begin operations immediately.

- No need to secure large amounts of land in metropolitan areas or pay land acquisition costs.

- Shortening of construction period. The conversion of used vessels to offshore data centers takes about one year, about three years less than the development of a conventional land-based data center.

- Mobility. Vessel-based offshore data centers are floating structures, so they can be moved to different locations in response to changes in demand. Depending on conditions, they can also be operated as data centers while navigating on the ocean like conventional vessels.

Advantages of converting used vessels into offshore data centers

- Reducing the environmental impact of raw material extraction and processing by utilizing existing vessel hulls. Reduction of initial investment and operating costs. In addition to reducing construction costs, the use of existing onboard systems (air conditioning, water intake, generators, etc.) is expected to reduce initial investment costs. In addition, water cooling systems that utilize seawater are energy efficient, reducing the amount of electricity consumed for server cooling and further reducing operating costs.

- Extensive space. Example: A car carrier with a floor area of approximately 54,000m2 is equivalent to one of Japan's largest land-based data centers in terms of total floor area.

This project leverages the MOL Group's assets and ship-related expertise to quickly build digital infrastructure while minimizing environmental impact. The group will continue to develop various social infrastructure businesses centered on the shipping industry, and will respond to the changing needs of society, including environmental conservation, through the advancement of its technology and services.